Hyundai Reveals its New Dedicated ‘E-GMP' Platform to Support its Goal to Become a Global EV Leader

【Summary】Hyundai Motor Group’s plans to introduce a total of 23 electrified models over the next several years, so the company built a dedicated EV platform to serve as the foundation for its future battery-electric vehicles. The automaker revealed its new modular Electric-Global Modular Platform (E-GMP) on Wednesday. The E-GMP represents an entirely new way of building vehicles for Hyundai.

With electric automaker Tesla now the world's most valuable car company, many of the world's automakers are racing to catch up in the electric vehicle space. Among them are Volkswagen, General Motors, and Hyundai.

Hyundai Motor Group plans to introduce a total of 23 electrified models over the next several years, so the company built a dedicated EV platform to serve as the foundation for its future battery-electric vehicles. The automaker revealed its new dedicated Electric-Global Modular Platform (E-GMP) on Wednesday.

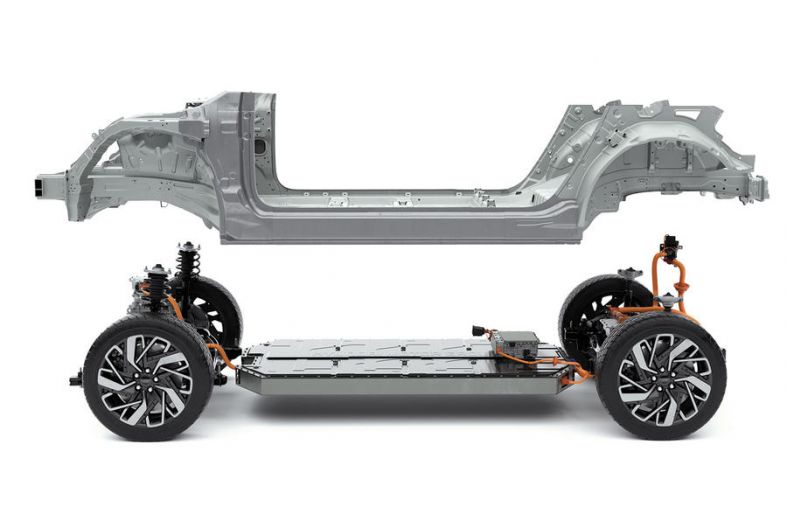

Without having to rely on a large internal combustion engine and drivetrain for propulsion, the E-GMP represents an entirely new way of building vehicles at Hyundai.

"E-GMP is the culmination of years of research and development and brings together our most cutting-edge technologies. Our BEV line-up will evolve and be strengthened by this innovative new platform," said Fayez Abdul Rahman, Senior Vice President of Vehicle Architecture Development Center for Hyundai Motor Group.

Hyundai is aiming to become one of the world's top three manufacturers of battery-powered vehicles. The company aims to sell 1 million electric vehicles each year to take a 10% share of electric vehicle sales to become a leader in the global market by 2025.

The fully-electric Ioniq 5 crossover will be the first vehicle launched by Hyundai Group that's built on the E-GMP.

The E-GMP also offers Hyundai greater flexibility in designing new battery-powered models. Unlike traditional vehicle platforms designed to accommodate a conventional internal combustion engine, Hyundai's new platform will offer more interior space for passengers or luggage since the electric motors and batteries take up less space.

With the battery pack mounted beneath the floor, the E-GMP creates a flat floor for the cabin, allowing Hyundai engineers greater flexibility in designing an EV's interior space. The flat floor offers more legroom for passengers as well as more arrangement options for the front and rear seats.

The E-GMP's electric powertrain consists of a powerful motor, EV transmission and inverter. These three components are integrated into a single compact module. Hyundai says this design allows the motor to operate at higher RPMs, up to 70% higher than existing motors to offer greater power.

The electric motor in the E-GMP is controlled by an inverter power module, which uses silicon carbide (SiC) semiconductors. Silicon carbide has benefits over traditional silicon chips, including better conductivity and cooling performance in high temperature environments.

The SiC chips are well suited for use in electric vehicles. SICs can enhance efficiency up to 3%, which means the vehicle can be driven for approximately 5 percent longer on the same battery energy.

Hyundai's new E-GMP is primarily designed for rear-wheel-drive electric vehicles and offers better weight distribution with the batteries mounted low in the floor, which improve overall handling and driving dynamics over front-wheel-drive setups. However, Hyundai said customers will be able to choose between rear-wheel and all-wheel drive configurations by adding an additional motor up front.

The all-wheel drive system includes an EV transmission disconnector, which controls the connection between the additional motor and front wheels. This allows drivers to switch between two-wheel and all-wheel drive modes for more power or to match driving conditions, such as driving in snow or rain.

"Today our front-wheel driven Hyundai and Kia BEVs are already among the most efficient ones in their segments," said Albert Biermann, President and Head of R&D Division for Hyundai Motor Group. "With our rear-wheel driven based E-GMP, we are extending our technological leadership into segments where customers demand excellent driving dynamics and outstanding efficiency."

Hyundai says the E-GMP is engineered to offer improved cornering performance and stability at higher speeds. This is primarily due to the platform's low center of gravity.

The E-GMP includes a five-link rear suspension system, which is typically found on larger sedans and luxury models. It also includes what Hyundai claims is the world's first mass-produced integrated drive axle (IDA).

The IDA integrates the drive shaft and the wheel bearings that connect the shaft to the wheels. It represents a departure from the traditional driveshaft setup that's been used in the auto industry for nearly 100 years. This design eliminates bolting the axle to a wheel hub. Hyundai says the design improves comfort and stability.

Like Volkswagen's MEB EV platform design to be the foundation of millions of electric models the automaker plans to produce, Hydundai's E-GMP is modular and shares components allowing for more flexibility to build different vehicles on the same platform. Hyundai's future EVs, including sedans, SUVs and crossovers will be built on the new E-GMP.

Hyundai says the battery pack for the E-GMP will be the most power-dense system that the company has ever created, with energy density enhanced by around 10% compared to existing EV battery technology. A high performance EV built on the E-GMP can accelerate from 0 to 60 mph in less than 3.5 seconds and achieve a maximum speed of 161 mph (260km/h).

A vehicle based on E-GMP is capable of a maximum range of over 310 miles (500km) according to the Worldwide Harmonized Light-duty vehicle Procedure (WLTP).

For added safety. The E-GMP is built with a battery support structure made of ultra-high strength steel. Hot-stamped steel components surround this structure for additional rigidity.

Hyundai also reinforced the structure located in front of the dashboard, in order to minimize the chance of damage to the power electric system and battery in the event of a collision.

Standardized Battery Module

All Hyundai Group electric vehicles developed with the E-GMP platform will utilize a standardized battery module. This module is composed of pouch-type battery cells and can be arranged in different quantities for each vehicle, allowing Hyundai to offer longer range on some models or more power on others.

The battery pack uses a separate cooling structure instead of integrating into the battery pack itself. This design helps make the battery pack more compact and lighter. The battery can also be tuned with software to maximize driving range, or deliver more power.

Multi (800V & 400V) and Bi-Directional Charging System

E-GMP offers 800V charging capability as standard and enables 400V charging, without the need for additional adapters, according to Hyundai. The automaker claims its new multi-charging system is a world's first technology which operates the motor and the inverter to boost 400V to 800V charging compatibility.

Most existing EVs and the fast-charging infrastructure provide charging rates of 50kW~150kW for EVs equipped with a 400V system. However some new EVs are being built with 800V architectures that support much faster charging rates up to 350kW, including the Porsche Taycan and upcoming Lucid Motors Air sedan. This higher charging rate can charge the battery to 80% in just 18 minutes, which adds 100km of driving range in just five minutes.

In addition, the E-GMP includes an Integrated Charging Control Unit (ICCU) that supports bi-directional charging. The ICCU can charge as well as discharge energy from the vehicle's battery without any additional components. This can be used to operate 110v or 220V electrical devices or even charge another EV.

To support the E-GMP higher charging rates, Hyundai invested in IONITY, a leading high-power EV charging network operator in Europe, as a strategic partner and shareholder.

IONITY currently operates 308 high-power charging (HPC) stations across Europe with charging capacity of up to 350 kW. The company plans to increase this number to 400 by 2022, including 51 currently under construction, Hyundai said.

Beginning in 2021, the E-GMP will underpin a wide range of new battery electric vehicles (BEVs) from the Hyundai Group, beginning with the IONIQ 5, a mid-size crossover due in the second half of 2021 under the automaker's new electric-only IONIQ sub-brand.

-

Ford is Testing a New Robotic Charging Station to Assist Drivers of EVs With Disabilities

-

Ford Raises the Prices of the F-150 Lightning Electric Pickup Due to Rising Raw Material Costs

-

The BMW 7-Series to Feature HD Live Maps From HERE Technologies for Hands-Free Highway Driving in North America at Speeds up to 80 MPH

-

AutoX to Use the 'Eyeonic Vision Sensor' from California-based SiLC Technologies for its Robotaxi Fleet in China

-

LG Develops ‘Invisible’ Speaker Sound Technology That Could Revolutionize In-Vehicle Audio

-

Researchers at South Korea’s Chung-Ang University Develop a ‘Meta-Reinforcement’ Machine Learning Algorithm for Traffic Lights to Improve Vehicle Throughput

-

Zeekr’s New 009 Electric Passenger Van is the World’s First EV to Feature CATL’s Advanced ‘Qilin’ Battery With a Range of 510 Miles

-

Redwood Materials is Building an Electric Vehicle Battery Recycling Facility in South Carolina

- General Motors is Doubling its Super Cruise Hands-Free Driving Network to 400,000 Miles of Roads in North America

- General Motors Announces Two Major Long-Term Supply Agreements for Enough Lithium and Cathode Material to Build 5 Million EVs

- Volvo Cars and Epic Games to Partner on a High-Resolution 3D Digital Driver’s Display Powered by the Unreal Engine

- LG Chem is Investing $3.2 Billion to Build a Cathode Manufacturing Facility for Electric Vehicle Batteries in Tennessee

- Here's One Way Lucid Motors Made the Air Sedan More Spacious for Passengers

- Consumer Reports Survey Finds Roughly 28% of Respondents Don't Want to Buy an EV

- Intel’s Self-Driving Car Unit Mobileye Postpones its Planned U.S. IPO That Could Value the Company up to $50 Billion

- Stellantis Acquires Autonomous Driving Software Startup aiMotive

- Reservations for the Electric Fisker Ocean SUV Reach 50,000, The Company Shares New Details About its Second EV Being Built by Foxconn

- Volkswagen Announces Pricing and Styling Updates for the 2023 ID.4 Electric SUV, Which is Being Assembled in Tennessee

About Us

About Us Contact Us

Contact Us Careers

Careers