48 Volt: Life-Support for the Internal Combustion Engine

【Summary】With governments such as Britain and France calling for restrictions on ICE (internal combustion engine) powered vehicles from 2040, new 48 volt electrical systems may just give the ailing technology a new lease on life.

With governments such as Britain and France calling for restrictions on ICE (internal combustion engine) powered vehicles from 2040, many pundits would have us believe that the internal combustion engine (ICE) is dead, or at least dying. While the patient is critical with a poor prognosis for recovery, life support is on its way that may just give the ailing technology a new lease on life.

Despite the noble intentions behind the proposed restrictions the fact is that Electric Vehicle (EV) sales last year made up less than one percent of total passenger vehicle sales globally. Moreover, when one considers the lack of infrastructure and the on-cost it seems to be a tall order to expect 100% of new vehicles sold in this market to be fully electrified in this timeframe.

However going electric is less about the practicality of rolling out the technology and more about governments' commitments to a cleaner environment; in particular as agreed to in the 2015 Paris Accord.

The pact, which came into force on 4 November 2016, sets out a comprehensive action plan to avoid dangerous climate change by limiting global warming to below 2°C.

To meet these objectives, CO2 emissions need to reduce by 85% in 35 years. This means reducing CO2 emissions by 2.6% per year on average, or 0.6 Gt per year in absolute terms.

ICEs won't simply disappear overnight

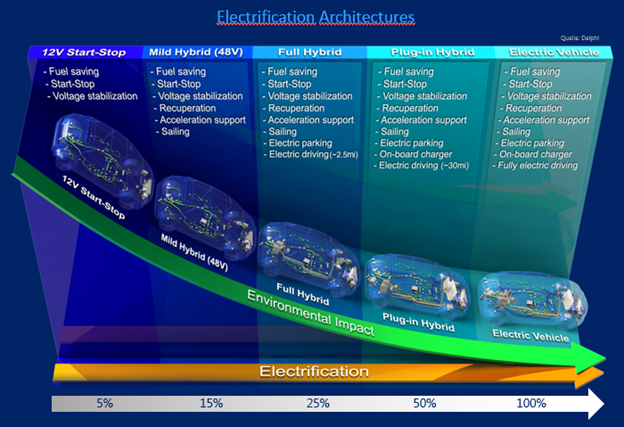

Notwithstanding the drive to roll out EVs, it's not possible to suddenly replace ICEs with fully electrified platforms, instead the approach to zero emissions will be evolutionary, albeit at a forced pace.

Image Source: ADD Solution

So, with the world saddled with ‘polluting' ICEs, and in particular NOx and particulate belching diesels, until well into the 21st century how will the accord achieve their ambitious targets?

While it is possible that improvements, such as downsizing/rightsizing and downspeeding may see some models meeting the 2020 emissions targets with current ICE technology, envisaged limits below 70 g/km are likely to be unattainable without some form of electrification.

But Plugin Hybrid EVs and Full EVs are expensive, so with manufacturers ideally targeting the cost of emissions reduction at about USD60 per gram of CO2 savings, the 48V Mild Hybrid Electric Vehicle (MHEV) offers an easy to implement solution that meets the cost constraints.

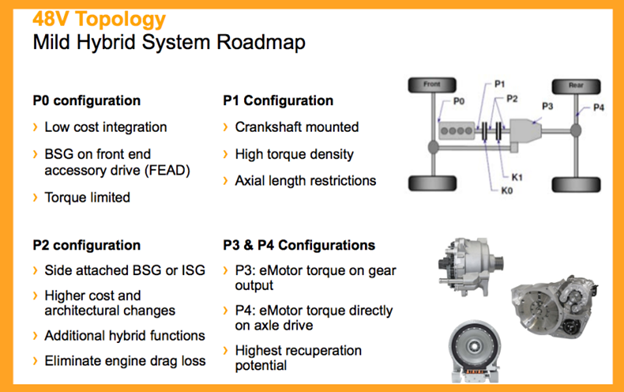

By fitting a Belt Starter Generator (BSG) that acts as a generator to recover energy under deceleration and serves as a motor to drive the crankshaft during acceleration, manufacturers have a cost effective, easily engineered solution to the pollution predicament they find themselves in.

At an on-cost of between USD1200 to USD2400, depending on the topology, a 48V MHEV can achieve up to 80% of the emissions savings of a Hybrid EV at between 30 to 50% of the cost. In tests conducted in Europe, this translates to an emissions reduction of between 12 to 15%, measured over the New European Driving Cycle (NEDC), and an impressive 20 to 28% over Real Driving Emissions (RDE) testing on the road.

Image Source: Jalopnik

In addition, as a P0 topology, the platform requires minimum engineering changes, and can be implemented well within a model cycle.

Efficient energy management reduces fuel consumption and emissions

As with other hybrid systems, the 48V MHEV relies on energy recovery which, even with the use of the least expensive BSG system, is capable of returning a 13% CO2 saving over the NEDC.

Primarily, this saving is made possible by using the energy harvested during braking or deceleration to enable torque assist when accelerating, thereby reducing engine load, and as a result, fuel consumption at selected points over the test cycle.

Energy recovery and torque assist are even more beneficial over the RDE where extended engine-off coasting phases are often encountered. In an evaluation of a 48V P0 system, on public roads in Germany, Continental found that 22% engine-off coasting could return a 8% fuel saving.

While these savings apply to both gasoline and diesel fuelled vehicles, the higher electrical power available from 48V opens the door for several innovative solutions to the diesel's woes.

Will 48V clean up the diesel act, or replace it?

Even before the VW emissions fracas, diesel powered vehicles were in the spotlight for particulate and NOx emissions. Post ‘dieselgate', the call for an end to diesel-power has raged unabated, mostly driven by indignant emotion.

While those not conversant with emissions regulations may not distinguish between GHG (CO2) and NOx and particulate emissions, diesels because of their advantage over gasoline-powered vehicles in terms of CO2 emissions, cannot be excluded as a green mode of transportation. And while NOx may be problematic in diesel exhaust gas emissions, the 48V MHEV can significantly reduce these as well.

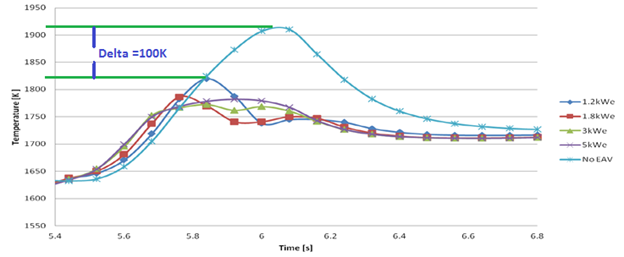

Although the fitment of a 48V eSuper Charger is primarily used in luxury vehicles such as the Audi SQ7 to reduce turbo lag and improve transient response, the additional air flow the unit provides during acceleration can also reduce combustion temperature by as much as 100°C during this phase, thereby curbing NOx formation.

Image source: Valeo

However, cleaning up the diesel act may already be too late: Cities such as London, Paris, Athens and Mexico City have already made it clear that from 2025 diesels will be banned from their streets which could very well see the end of this energy source in passenger transport.

Should this be the case, the 48V MHEV could very well step in to replace the diesel as a fuel efficient, clean and cost effective form of transportation. Coming in at a similar cost to a Micro Hybrid (Stop/ start) diesel, a gasoline powered MHEV can achieve similar fuel consumption but without the attendant harmful emissions.

At last downsized engines live up to their emissions promise

For more than a decade now, manufacturers have been touting downsizing and downspeeding as a crucial tool in the strategy to meet emissions and fuel consumption reductions. 4.0L V8s have become 3.0L V6s, and 2.0L I4s have shrunk to 999Cm3 I3s, all claiming to satisfy customers and regulators alike:

· The Ford EcoBoost is found in eight Blue Oval models, including the hefty Grand C-Max and the Mondeo.

· BMW's modular 1.5-liter triple is installed on everything from the Mini Cooper to the far chunkier Countryman

· The Fiat two-cylinder TwinAir engine is also fitted to the Alfa Romeo MiTo hatch

· Opel puts its 1.0-liter triple in the Adam, the Corsa, and the Astra

· Renault stretches its 900cc unit up to the Captur and the Clio

· Volvo has gone for 2.0-liter, four-cylinder engines across the board, even on the giant XC90 SUV in supercharged and turbocharged form

· There is a 2.0-liter, four-cylinder option for Cadillac's giant CT6 limousine.

· Small four-cylinder diesels drive big SUVs from Mercedes-Benz and BMW

While these platforms perform well under laboratory testing, they do not do as well in the real-world: Results recorded in tests conducted by Emissions Analytics' EQUA initiative indicate that the differences measured between tests and real-world consumption were particularly pronounced in downsized engines.

The Emissions Analytics test of more than 500 cars in real-world testing found that by far the largest variance over the claimed consumption figures came from engines below 1.0 liter.

The 10 models with the highest percentage difference in the EQUA test all used downsized engines, including the Fiat and Alfa Romeo Twin Air, the Mini One three-cylinder engine and the smart range of 0.6-liter, three-cylinder turbocharged engines.

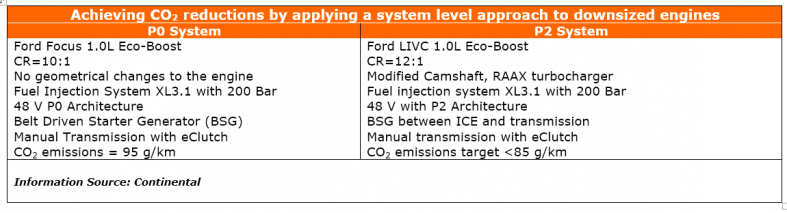

Independent of these findings, joint trials involving Schaeffler, Ford, and Continental proved that real-world CO2 reductions could be achieved in downsized engines through an optimized 48V strategy using the right topology and an appropriately configured engine.

Moreover, as an additional bonus for manufacturers that employ the 48V powernet to achieve CO2 savings, once the 48V architecture has been implemented the additional power available can be put to use to offer consumers comfort features that they perceive as adding value to their purchase. It is far easier to sell the features rather than the emissions savings.

So, while EVs will be the end-game, the esteemed ICE seems set on a new lease of life with less emissions than could ever have been imagined at the turn of the century.

-

FEATURED COVERAGE: Testing Autonomous Vehicles to Save Lives in the Wake of Recent Accidents

-

SPECIAL FEATURE: 5G Will Revolutionize Cars and the Networks That Support Them

-

SPECIAL FEATURE: Unraveling the DNA of the Car of the Future, Part Three

-

SPECIAL FEATURE: Unraveling the DNA of the Car of the Future, Part Two

-

Sensors give smart cars a sixth sense

-

The give and take of EV charging

-

Is China’s NEV Program a Step Too Far?

-

Is 2170 Tesla’s Magic Number?

- Tesla's Battery Supplier CATL Unveils its New ‘Qilin’ Battery That Can Deliver 600+ Miles of Range to EVs

- Tesla Sells 100,291 China-Built Vehicles in November, a Record High

- Mercedes-Benz is Offering a Performance Upgrade as a Yearly Subscription on its EQ Electric Vehicles

- NHTSA Opens Investigations Into Two New Fatal Tesla Accidents

- The Polestar 5 Sedan Will Have Dual Electric Motors With 884 HP

- California DMV Accuses Tesla of Making False Claims About its Driver-Assist Systems

- Toyota is Investing an Additional $2.5 Billion to Expand its North Carolina Factory to Boost EV Battery Production

- Tesla Rival XPeng Inc. to Start Deliveries of its New Flagship G9 Electric SUV in September, CEO Confirms After Sharing New Details

- $12,500 Federal EV Tax Credit Proposal Reportedly Dropped

- Tesla Raises Prices in the U.S. as Inflation Chips Away at its Profit Margins

About Us

About Us Contact Us

Contact Us Careers

Careers