General Motors is Building a Joint Venture Cathode Material Processing Plant in the U.S. for Electric Vehicle Batteries

【Summary】General Motors today announced plans with South Korean battery materials company POSCO Chemical to form a joint venture to construct a factory in North America to process battery materials for GM’s Ultium electric vehicle platform. The new facility will supply GM’s two Ultium Cell factories that the automaker and its battery partner LG Energy are building in Lordstown, Ohio and Spring Hill, Tennessee.

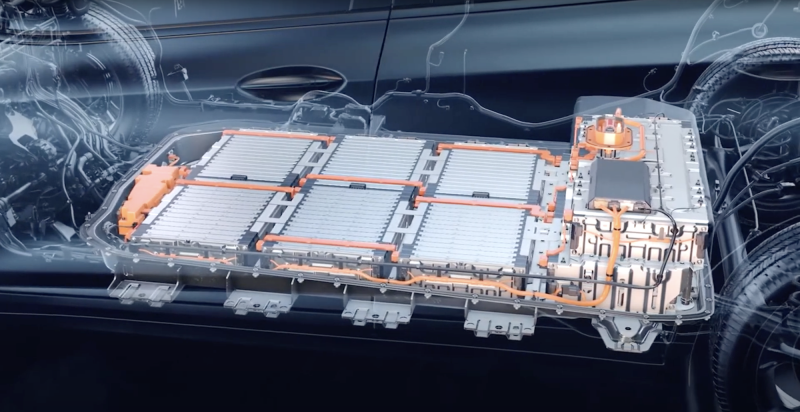

General Motors today announced plans with South Korean battery materials company POSCO Chemical to form a joint venture to construct a factory in North America to process battery materials for GM's Ultium electric vehicle platform, which will underpin future models from the automaker. The joint venture will process what's called "Cathode Active Material" or CAM, which is a key battery material. CAM represents about 40 percent of the cost of a battery cell, according to GM. GM and POSCO Chemical have signed a non-binding term sheet to create the joint venture and expect to execute definitive agreements shortly. "Our work with POSCO Chemical is a key part of our strategy to rapidly scale U.S. EV production and drive innovation in battery performance, quality and cost," said Doug Parks, GM executive vice president, Global Product Development, Purchasing and Supply Chain. "We are building a sustainable and resilient North America-focused supply chain for EVs covering the entire ecosystem from raw materials to battery cell manufacturing and recycling." The location of the facility, which GM said will create hundreds of jobs when it opens in 2024, will be announced at a later date. The new facility will supply GM's two Ultium Cell factories that its partner LG Energy are building in Lordstown, Ohio and Spring Hill, Tennessee. One possible location for the new joint venture cathode material plant is in Tennessee. In April, Ultium Cells LLC, the joint venture of LG Energy Solution and GM, announced a $2.3 billion plus investment to build a second EV battery cell manufacturing plant in Spring Hill, where the automaker has had a presence since 1990 when its opened its Spring Hill Manufacturing plant. The state-of-the-art Spring Hill plant will employ advanced manufacturing processes to produce battery cells more efficiently, with little waste, according to GM. It's also designed to be flexible enough to adapt to new advancements in EV battery technology. The new battery plant is part of GM's mission to drive down the cost of batteries through economies of scale. The Spring Hill plant is also the largest GM production facility in North America producing roughly 4.5 million GM vehicles since 1996. It will soon begin producing electric vehicles. GM announced in Oct 2020 that it will invest $2 billion in its Spring Hill Manufacturing facility to build fully-electric vehicles, including the upcoming Cadillac LYRIQ crossover, the first electric vehicle from GM's luxury division. The LYRIQ will be the first EV produced at GM's Spring Hill assembly plant. POSCO Chemical produces high-capacity Ni-rich cathode materials and low-expansion anode materials for EV batteries. The company also develops NCMA cathode, silicon anode and materials for solid-state batteries which contain no liquid electrolyte. "We are very pleased to participate in the global battery supply chain project with General Motors," said Kyung-Zoon Min, the CEO of POSCO Chemical. "Through close partnership, we will innovate battery materials and contribute to accelerate the adoption of EVs based on our world-class product development, mass production capacity, and raw materials competitiveness." GM is investing billions of dollars to electrify its model lineup. The automaker is investing $35 billion from 2020 to 2025 in electric vehicle development and autonomous driving. The plans include investments in EV battery manufacturing to supply the millions of EVs GM plans to build. Of the more than 30 EVs GM's plans to launch globally by 2025, more than two-thirds will be sold in the U.S. Globally, GM plans to deliver more than 1 million EVs annually by 2025, so the automaker is putting the pieces together to ensure it has the advanced batteries its needs to be competitive in the EV space. In October, GM announced its opening a new battery engineering center in Michigan to accelerate the development of more affordable electric vehicle batteries that offer longer driving ranges. GM named the battery engineer center the "Wallace Battery Cell Innovation Center" as a tribute to Bill Wallace, former director of Battery Systems and Electrification at GM. Wallace is best known for leading the team that designed and released GM's advanced automotive battery systems for the plug-in hybrid Chevrolet Volt, Malibu Hybrid and Bolt EV. The Wallace Center will help GM to accelerate the development of new EV battery technologies, including lithium-metal, silicon and solid-state batteries. But the facility will also develop advanced production methods that can quickly be deployed at GM's battery cell manufacturing plants. The Michigan plant will include cell test chambers, cell formation chambers, a material synthesis lab where GM can design its own cathode active materials, an electrolyte production lab and a forensics lab with material analysis equipment. The Wallace Center is expected to build batteries ranging in energy density from 600 to 1200 kWh/per liter, which could deliver ranges of 600 miles for GM's future EVs.

-

Ford is Testing a New Robotic Charging Station to Assist Drivers of EVs With Disabilities

-

Ford Raises the Prices of the F-150 Lightning Electric Pickup Due to Rising Raw Material Costs

-

The BMW 7-Series to Feature HD Live Maps From HERE Technologies for Hands-Free Highway Driving in North America at Speeds up to 80 MPH

-

AutoX to Use the 'Eyeonic Vision Sensor' from California-based SiLC Technologies for its Robotaxi Fleet in China

-

LG Develops ‘Invisible’ Speaker Sound Technology That Could Revolutionize In-Vehicle Audio

-

Researchers at South Korea’s Chung-Ang University Develop a ‘Meta-Reinforcement’ Machine Learning Algorithm for Traffic Lights to Improve Vehicle Throughput

-

Zeekr’s New 009 Electric Passenger Van is the World’s First EV to Feature CATL’s Advanced ‘Qilin’ Battery With a Range of 510 Miles

-

Redwood Materials is Building an Electric Vehicle Battery Recycling Facility in South Carolina

- Hyundai Motor Group Signs MoU with SK On Co. to Secure Batteries for EVs Built in the U.S.

- Electric Automaker Lucid Group Unveils the Lower Priced Air Pure and Air Touring Models

- Mercedes-Benz is Partnering with Game Engine Developer Unity Technologies to Create Immersive, 3D Infotainment Screens and Displays for its Future Vehicles

- Tesla Rival XPeng Inc. to Start Deliveries of its New Flagship G9 Electric SUV in September, CEO Confirms After Sharing New Details

- Volvo Offers a Sneak Peak of its New Flagship EX90 Electric SUV Ahead of its Upcoming Reveal on Nov 9

- Tesla Challenger NIO Inc Reports its Highest-Ever Monthly Sales in June

- Volvo is Building a New EV Service and Training Facility at its U.S. Headquarters in New Jersey To Fast Track its Electrification Plans

- GM Launches its Dealer Community Charging Program, Aims to Install 40,000 EV Chargers in Rural Areas and Small Towns Across the U.S.

- AI-Powered Computer Vision Perception Developer StradVision Closes on $88 Million Series C Funding Round

- The World’s First Level-4 Automated Parking Feature Developed by Mercedes-Benz and Bosch is Approved for Commercial Use

About Us

About Us Contact Us

Contact Us Careers

Careers