Solid State Battery Startup Solid Power Completes its EV Cell Pilot Production Line

【Summary】Solid state battery startup Solid Power announced the completion of its pilot production line that will produce the first advanced battery cells for electric vehicles that can deliver longer ranges. The company has dubbed it the “EV cell pilot line”. Solid Power will produce the first energy dense Silicon EV Cells for internal testing before delivering them to its automotive partners BMW and Ford Motor Co. for further automotive qualification testing.

Colorado-based solid state battery startup Solid Power announced the completion of its pilot production line that will produce the first advanced battery cells for electric vehicles that can deliver longer ranges. The company has dubbed it the "EV cell pilot line".

Solid Power will produce the first energy dense Silicon EV Cells for internal testing before delivering cells to its automotive partners BMW and Ford Motor Co. for further automotive qualification testing, which is planned by the end of the year.

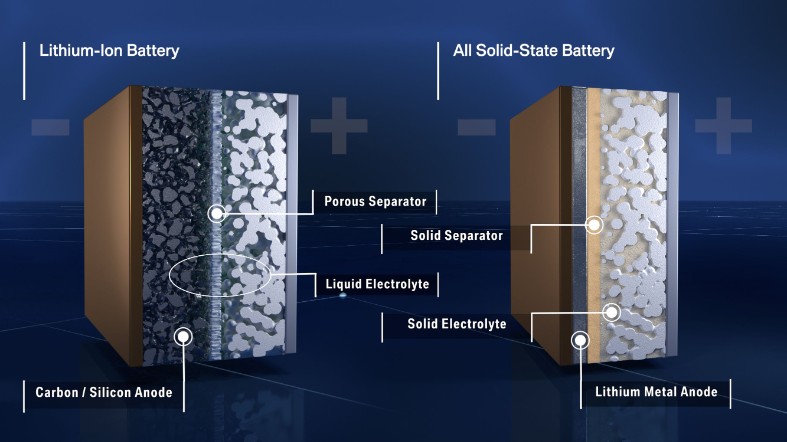

Solid state batteries have several advantages over conventional lithium-ion batteries, including enhanced safety characteristics. Solid state battery cells do not contain flammable liquid electrolytes. Ford confirmed that these enhanced safety characteristics were a motivating factor in Ford's investment in Solid Power.

"Solid Power is encouraged by taking this next step on its automotive qualification roadmap," said Doug Campbell, Chief Executive Officer of Solid Power. "The installation of this EV cell pilot line will allow us to produce EV-scale cells suitable for initiating the formal automotive qualification process. Over the coming quarters, we will work to bring the EV cell pilot line up to its full operational capability and look forward to delivering EV-scale all-solid-state cells to our partners later this year."

In May of last year, both Ford and BMW announced they were boosting their investments in Solid Power. The new investment follows Ford's initial investment in the company in 2019 and BMW's separate investment in 2017.

The two automakers contributed to a $130 million Series B investment round in which the BMW Group became an equal equity owner along with Ford. Ford said its additional equity investment will help accelerate further development of solid-state vehicle battery technology.

Also participating in the funding round last year was Volta Energy Technologies, a venture capital firm spun out of the U.S. Department of Energy's Argonne National Laboratory that's focused on investing in breakthrough energy storage and battery innovations.

Solid-state EV batteries have no liquid electrolyte and can be made smaller, lighter and more energy dense.

Solid Power's Advanced Battery Technology

Solid Power developed sulfide-based solid-state battery cells, which can be produced on existing lithium-ion battery manufacturing lines. The solid state batteries use lithium metal as the anode (conductive) material, which is not typically used in rechargeable batteries due to its tendency to develop "dendrite" growth, which can short circuit a battery.

Dendrites are tiny, rigid tree-like structures that can grow inside a lithium-ion battery. The needle-like dendrite projections are called "whiskers". The formation of rigid dendrites can pierce the separator inside a battery leading to a short circuit or battery fire. Dendrites also increase unwanted reactions between the electrolyte and the lithium, which can eventually lead to premature battery failure.

To overcome this challenge, Solid Power's batteries have a solid electrolyte-separator layer, which allows for uniform plating and stripping of Lithium Metal ("Li metal") without formation of dendrites or consumption of the electrolyte. Solid Power's advanced batteries contain 50% active silicon in the anode, which results in increased energy density that can significantly increase an EV's range.

Solid Power's EV cell pilot line is designed to produce large-format sulfide-based cells in a manner that mimics the traditional lithium-ion production processes.

When running at full capacity, Solid Power says its EV cell pilot line is expected to be capable of producing 300 cells per week, or approximately 15,000 cells per year, with the majority of those being planned for automotive qualification testing.

"With the EV cell pilot line now installed, our next big challenge is commencing production at scale and building cells that meet the requirements necessary for us to enter into automotive qualification later this year," said Derek Johnson, Chief Operating Officer at Solid Power.

Solid Power expects to be able to optimize its Silicon EV Cells for capacities ranging from 60 to 100 Ah.

Under the new agreement with Ford announced last year, the automaker will receive full-scale 100 ampere hour (Ah) cells for testing and integration into its future EVs. Ford also has a separate joint development agreement with Solid Power to develop and test its specific battery cell design and help streamline Ford's integration into future vehicles.

BMW will also receive 100 Ah cells for qualification testing and vehicle integration.

Solid Power says this flexibility in producing various Ah battery cells will better meet its automotive partners' needs.

-

Ford is Testing a New Robotic Charging Station to Assist Drivers of EVs With Disabilities

-

Ford Raises the Prices of the F-150 Lightning Electric Pickup Due to Rising Raw Material Costs

-

The BMW 7-Series to Feature HD Live Maps From HERE Technologies for Hands-Free Highway Driving in North America at Speeds up to 80 MPH

-

AutoX to Use the 'Eyeonic Vision Sensor' from California-based SiLC Technologies for its Robotaxi Fleet in China

-

LG Develops ‘Invisible’ Speaker Sound Technology That Could Revolutionize In-Vehicle Audio

-

Researchers at South Korea’s Chung-Ang University Develop a ‘Meta-Reinforcement’ Machine Learning Algorithm for Traffic Lights to Improve Vehicle Throughput

-

Zeekr’s New 009 Electric Passenger Van is the World’s First EV to Feature CATL’s Advanced ‘Qilin’ Battery With a Range of 510 Miles

-

Redwood Materials is Building an Electric Vehicle Battery Recycling Facility in South Carolina

- Consumer Reports Survey Finds Roughly 28% of Respondents Don't Want to Buy an EV

- Mazda Outlines Plans to Invest $10.6 Billion in Electric and Hybrid Vehicle Development Through 2030

- Solar-Electric Car Developer Lightyear Announces Technical Partnership with Hypercar Manufacturer Koenigsegg

- NHTSA Upgrades Tesla's Autopilot Investigation to 'Engineering Analysis'

- BMW Expands i4 Lineup With the Affordable eDrive35

- Elon Musk Wants to Cut Around 10% of Tesla’s Global Workforce, Blames Economic Uncertainty

- GM Launches its Dealer Community Charging Program, Aims to Install 40,000 EV Chargers in Rural Areas and Small Towns Across the U.S.

- EV Charging Provider Electrify America Raises $450 Million, Siemens to Become a Minority Shareholder

- Ford Motor Co is Cutting 3,000 Jobs as it Transitions to Electric Vehicles, Software and Digital Services

- New Intelligent EV Company JiDU Reveals its Revolutionary Concept Production 'Robocar'

About Us

About Us Contact Us

Contact Us Careers

Careers