Lucid Group to Integrate Wolfspeed's Silicon Carbide (SiC) Semiconductors in the Lucid Air Sedan as Part of a New Supply Agreement

【Summary】Wolfspeed, a leading developer of Silicon Carbide (SiC) semiconductor technology, today announced that luxury electric automaker Lucid Motors will use its Silicon Carbide power solutions in the high-performance Lucid Air sedan. SiC technology has many benefits over traditional silicon chips, including better conductivity and cooling performance in high temperature environments, which makes them well suited for use in electric vehicles.

Wolfspeed, a leading developer of Silicon Carbide (SiC) semiconductor technology, today announced that luxury electric automaker Lucid Motors will use its Silicon Carbide power device solutions in the high-performance Lucid Air sedan.

Wolfspeed and Lucid have entered into a multiyear agreement in which Wolfspeed will produce and supply Silicon Carbide devices to the company.

The advanced Silicon Carbide semiconductors will be produced at Wolfspeed's new $1 billion state-of-the-art Mohawk Valley Fab in Marcy, New York, which is opening on April 25. The facility will significantly increase capacity for Wolfspeed's Silicon Carbide business and support the transition from traditional silicon-based semiconductors, the company said.

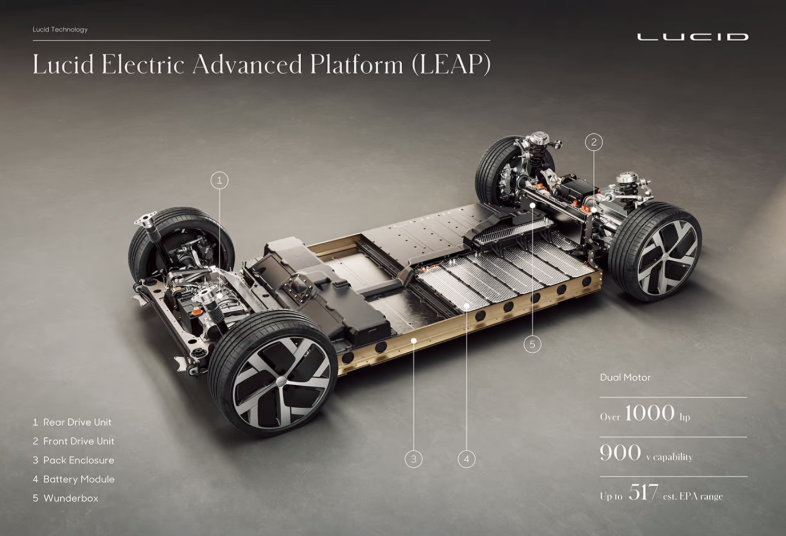

The facility will be the world's largest 200-millimeter Silicon Carbide fabrication facility and dramatically expand production capacity of Wolfspeed's power devices. This partnership gives Lucid access to increased capacity to better support their long-term automotive production, which includes an electric SUV in development under the codename "Project Gravity".

"Lucid Motors is an emerging leader in not only electric vehicles, but the entire automotive industry," said Gregg Lowe, CEO of Wolfspeed. "As the world advances towards an all-electric future for transportation, Silicon Carbide technology is at the forefront of the industry's transition to EVs, enabling superior performance, range and charge time. Our investment in the Mohawk Valley Fab ensures our customers, including Lucid, have access to the advanced products they need to deliver innovative solutions to the market."

How Wolfspeed's Silicon Carbide Semiconductors Improve the Performance of EVs

Silicon carbide has many benefits over traditional silicon chips, including better conductivity and cooling performance in high temperature environments, which makes them well suited for use in electric vehicles.

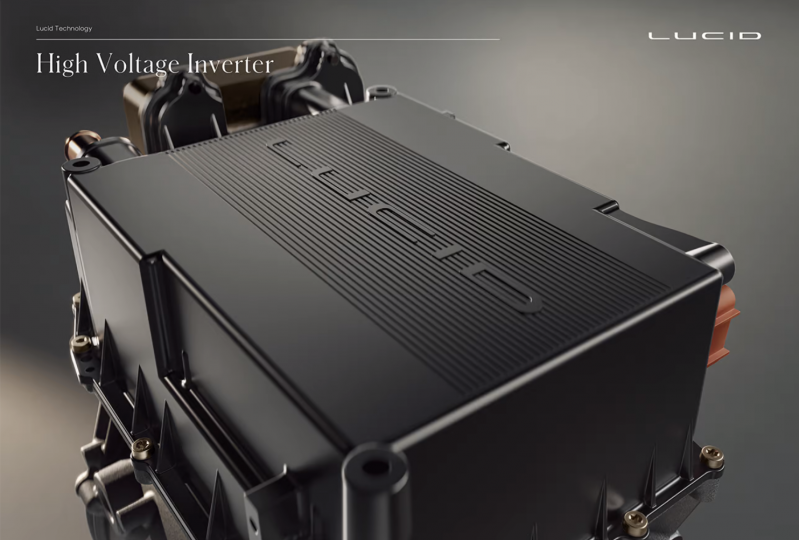

In an electric vehicle's powertrain, an inverter converts direct current (DC) to alternating current (AC) and controls the flow of electricity from the battery or from the battery pack to the electric motor(s). Silicon carbide-based inverters are capable of delivering a more rapid flow of power to the wheels when the driver demands it, such as during hard acceleration.

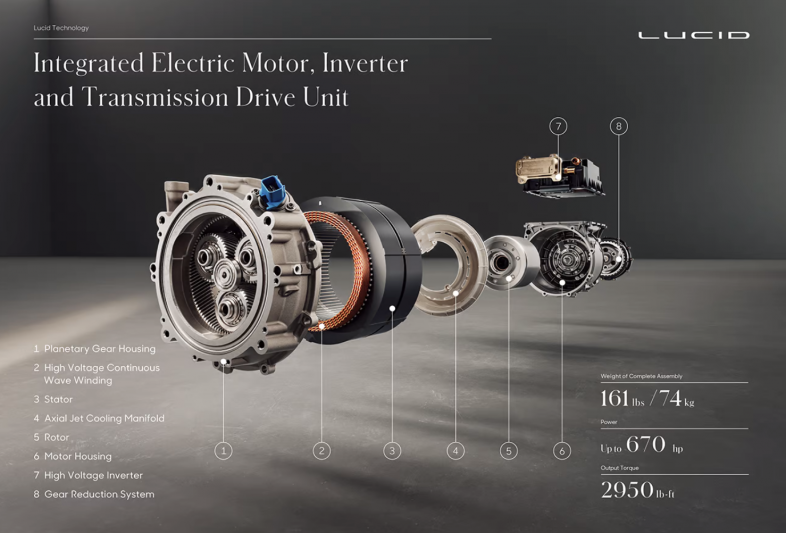

This benefit allows automakers the option of using smaller electric motors without sacrificing power output. The electric motors can also be made lighter and operate more efficiently, which can also help to increase range.

It's what Lucid achieved with the Air sedan. The Air's electric powertrain is highly efficient, so Lucid was able to "miniaturize" it and make it smaller and lighter, while still offering an industry-leading range of over 500 miles.

Silicon carbide also delivers better thermal conductivity, which is important for high-RPM, high-voltage electric motors to prevent overheating.

The Lucid Air's inverters feature Wolfspeed's XM3 Silicon Carbide power modules. The modules offer low switching losses, minimal resistance, and high power density, according to Wolfspeed. The XM3 power modules contribute to the efficiency and power density of the proprietary 670 horsepower electric motor in the Lucid Air, which weighs just 163 pounds.

Since silicon carbide inverters produce less heat and are less temperature-sensitive. These inverters also have reduced cooling demands and a smaller form factor, making them ideal for electric vehicles where size and weight are concerns.

"Lucid's proprietary powertrain technology – engineered and produced in-house – is at the core of what makes Lucid Air the most advanced and most efficient luxury electric vehicle in the world," said Eric Bach, Senior Vice President of Product and Chief Engineer at Lucid. "With the perfect blend of high performance and high efficiency, Wolfspeed's innovative Silicon Carbide MOSFET power semiconductors are an ideal fit for Lucid's advanced technology."

Tesla was the first automaker to add SiC metal-oxide-semiconductor field-effect transistors (MOSFETs) to an inverter design the company sourced from its supplier STMicroelectronics for the Model 3.

In Tesla's Model 3, the use of SiC in the inverter reduced the overall weight of it to 4.8kg, which is less than half the weight of the inverter used in the 2019 Nissan Leaf, which weighs in at 11.1kg.

The new partnership between Wolfspeed and Lucid Motors follows a separate strategic supplier agreement partnership with automaker General Motors announced in Oct 2021. As part of the agreement with GM, Wolfspeed will develop and provide silicon carbide (SiC) power solutions for the automaker's future electric vehicles.

GM is participating in the "Wolfspeed Assurance of Supply Program" (WS AoSP), which is intended to secure domestic, sustainable and scalable materials for EV production in the U.S. The silicon carbide power devices for GM will also be produced at Wolfspeed's Mohawk Valley Fab in Marcy.

GM will use the silicon carbide technology supplied by Wolfspeed for the integrated power electronics of GM's new Ultium Drive units that will power the company's next-generation EVs. Wolfspeed's silicon carbide devices will enable GM to develop more efficient EV powertrains that offer longer ranges.

Chinese electric vehicle startup NIO Inc, which is one of Tesla's biggest competitors in China, will also use a new silicon carbide (SiC) electric drive system in its future EVs, beginning with the company's ET7 sedan. In June 2021, NIO announced that the first C-Sample of its new SiC powertrain rolled off the assembly line.

As automakers switch from 400-volt electrical systems to more powerful 800-volt systems used in the Porsche Taycan, the role of the inverter in an EV as a core part of the overall system is becoming more important, as it can deliver higher current more efficiently.

South Korea automaker Hyundai was one of the first automakers to commercialize 800-volt systems with its new Electric-Global Modular Platform (E-GMP), which underpins the IONIQ 5 electric SUV.

Hyundai says the crossover model can reach an 80% charge in 18 minutes on a fast charger. This is roughly a fifth of the time a conventional 400-volt car needs to reach the same charge. By using an SiC inverter means more of this power is made available to propel the vehicle.

Earlier this month, Lucid announced a brand new version of its Air sedan called Lucid Air Grand Touring Performance, which is the most powerful electric vehicle on sale in North America. Customer deliveries in the U.S. are slated to begin in June 2022 and by August 2022 in Canada.

The dual-motor Lucid Air Grand Touring Performance delivers 1,050 horsepower with an EPA-estimated driving range of 446 miles. The dual-motor setup on the front and rear axles can propel the Air Grand Touring Performance from 0 to 60 miles per hour in just 2.6 seconds.

For comparison, the Lucid Air Grand Touring is rated at 819 horsepower, with a 0 to 60 mph acceleration time of 3 seconds and a range of 516 miles.

The Lucid Air also features an ultra-fast 900-volt charging system, enabling users to add up to 300 miles of range in just 21 minutes at a 350 kW DC fast charger.

The Lucid Air was recently named the 2022 MotorTrend Car of the Year. The vehicle is being produced at Lucid's factory in Casa Grande, Arizona.

-

Ford is Testing a New Robotic Charging Station to Assist Drivers of EVs With Disabilities

-

Ford Raises the Prices of the F-150 Lightning Electric Pickup Due to Rising Raw Material Costs

-

The BMW 7-Series to Feature HD Live Maps From HERE Technologies for Hands-Free Highway Driving in North America at Speeds up to 80 MPH

-

AutoX to Use the 'Eyeonic Vision Sensor' from California-based SiLC Technologies for its Robotaxi Fleet in China

-

LG Develops ‘Invisible’ Speaker Sound Technology That Could Revolutionize In-Vehicle Audio

-

Researchers at South Korea’s Chung-Ang University Develop a ‘Meta-Reinforcement’ Machine Learning Algorithm for Traffic Lights to Improve Vehicle Throughput

-

Zeekr’s New 009 Electric Passenger Van is the World’s First EV to Feature CATL’s Advanced ‘Qilin’ Battery With a Range of 510 Miles

-

Redwood Materials is Building an Electric Vehicle Battery Recycling Facility in South Carolina

- Volkswagen CEO Believes It Will Overtake Tesla in EV Sales by 2025

- Hyundai's 2022 IONIQ 5 Electric SUV Awarded an IIHS 'Top Safety Plus' Rating

- Solar-Electric Car Developer Lightyear Announces Technical Partnership with Hypercar Manufacturer Koenigsegg

- US-listed LiDAR Developers Velodyne and Ouster to Merge in an All-Stock Deal

- Volkswagen’s Software Company CARIAD to Use BlackBerry QNX to Support ADAS and Autonomous Driving Functions of Future VW Vehicles

- Honda's New EV Friendly Retail Plans Hint at the End of Mega Dealerships

- Volkswagen Starts Production of the Electric ID.4 SUV in Tennessee, Presents New Competition for Tesla, GM and Ford

- Tesla Rival XPeng and Alibaba Cloud Set Up China’s Largest Cloud-Based Computing Center to Train Machine Learning Models for Autonomous Driving

- The NIO ET7 Will Come Standard With an Advanced Dolby Atmos-Powered Sound System Co-Developed With Audio Pioneer Dirac

- Rivian Discontinues Base Model for R1S, R1T

About Us

About Us Contact Us

Contact Us Careers

Careers